| Catalog Number | Dimensions | |||||

|---|---|---|---|---|---|---|

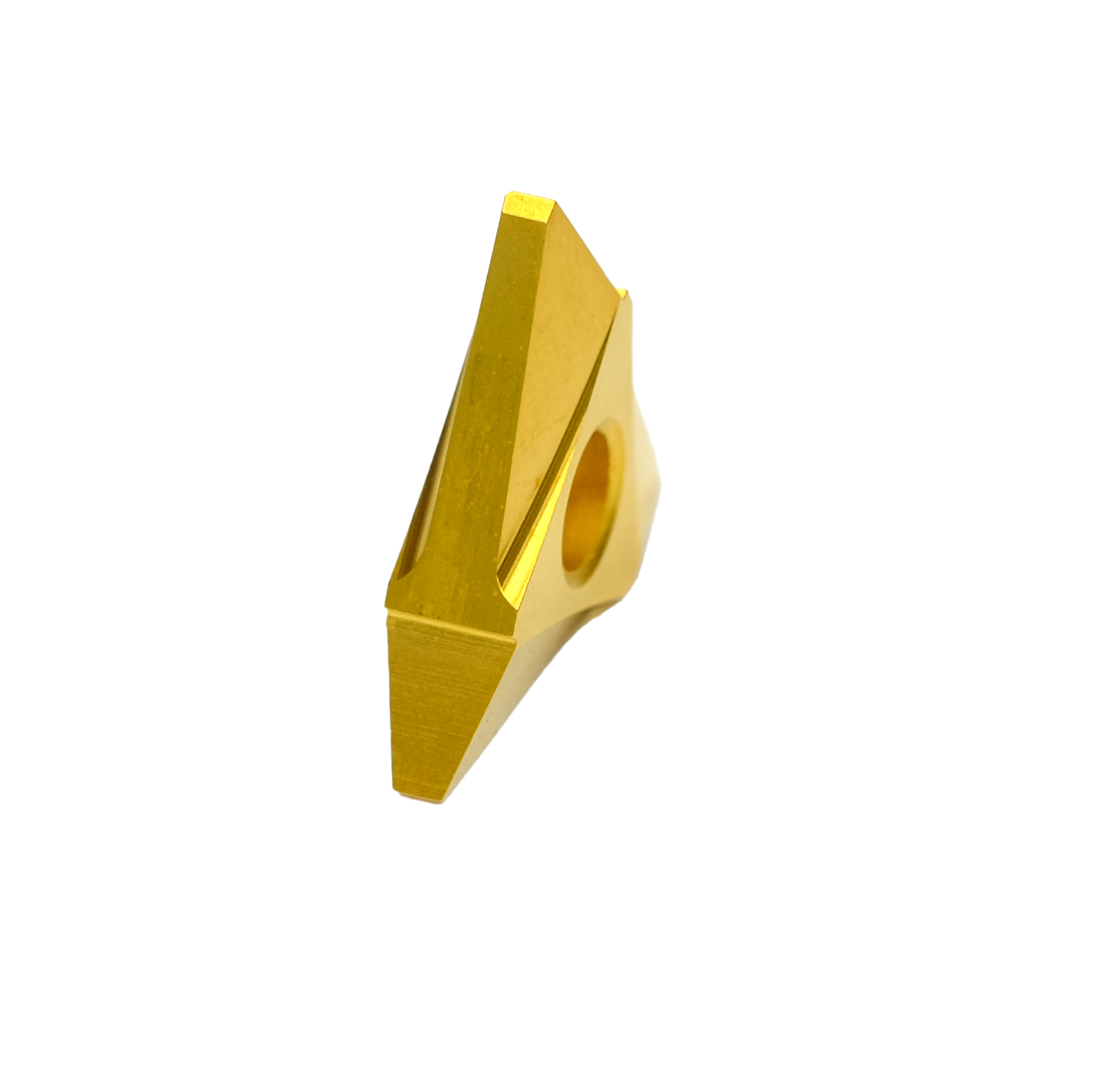

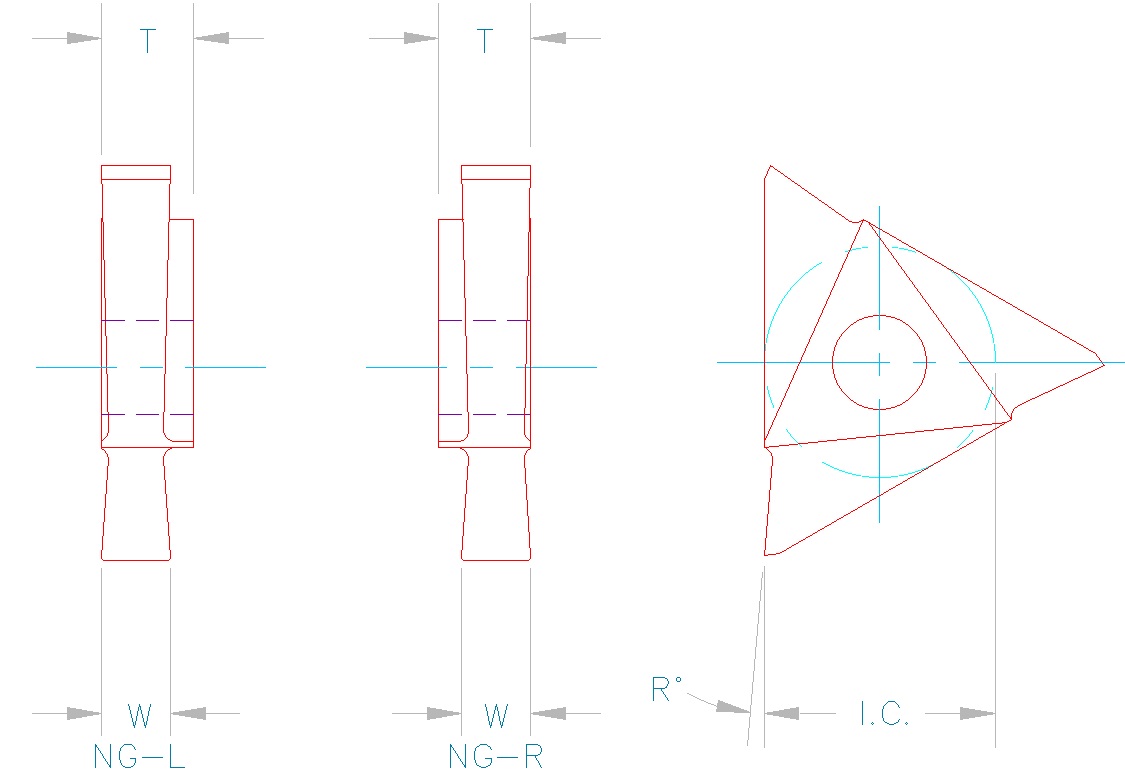

| Right Hand Left Hand | I.C. | Thk. | R° | W* | ||

| Min. | Max. | |||||

| TPMA 32 NGR | TPMA 32 NGL | 3/8 | .125 | 5° | 1/16 | 1/8> |

| TPMA 43 NGR | TPMA 43 NGL | 1/2 | .187 | 5° | 1/8 | 3/16 |

| TPMA 54 NGR | TPMA 54 NGL | 5/8 | .250 | 5° | 3/16 | 1/4 |

| TPMA 64 NGR | TPMA 64 NGL | 3/4 | .250 | 5° | 3/16 | 1/4 |

| TPMA 66 NGR | TPMA 66 NGL | 3/4 | .375 | 5° | 3/16 | 3/8 |

| TPMA 32 NGR 10° | TPMA 32 NGL 10° | 3/8 | .125 | 10° | 1/16 | 1/8> |

| TPMA 43 NGR 10° | TPMA 43 NGL 10° | 1/2 | .187 | 10° | 1/8 | 3/16 |

| TPMA 54 NGR 10° | TPMA 54 NGL 10° | 5/8 | .250 | 10° | 3/16 | 1/4 |

| TPMA 64 NGR 10° | TPMA 64 NGL 10° | 3/4 | .250 | 10° | 3/16 | 1/4 |

| TPMA 66 NGR 10° | TPMA 66 NGL 10° | 3/4 | .375 | 10° | 3/16 | 3/8 |

• * “W” Dimension must be specified when ordering.

• Style TPMC (inserts with corner radii), or full radius inserts are available.

• Inserts with “W” min. less than shown available on a quotation basis only

• Style TPMA NG 10˚ inserts are for use only with style HTHPR heads.